Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum). The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies, it rapidly cools and solidifies into the final part, called the casting. The steps in this process are described in greater detail in the next section. The castings that are created in this process can vary greatly in size and weight, ranging from a couple ounces to 100 pounds. One common application of die cast parts are housings - thin-walled enclosures, often requiring many ribs and bosses on the interior. Metal housings for a variety of appliances and equipment are often die cast. Several automobile components are also manufactured using die casting, including pistons, cylinder heads, and engine blocks. Other common die cast parts include propellers, gears, bushings, pumps, and valves.

Friday, 17 June 2011

NewDie Casting

Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum). The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies, it rapidly cools and solidifies into the final part, called the casting. The steps in this process are described in greater detail in the next section. The castings that are created in this process can vary greatly in size and weight, ranging from a couple ounces to 100 pounds. One common application of die cast parts are housings - thin-walled enclosures, often requiring many ribs and bosses on the interior. Metal housings for a variety of appliances and equipment are often die cast. Several automobile components are also manufactured using die casting, including pistons, cylinder heads, and engine blocks. Other common die cast parts include propellers, gears, bushings, pumps, and valves.

Tuesday, 14 June 2011

May 29, 2011 Slideshow

May 29, 2011 Slideshow: "TripAdvisor™ TripWow ★ May 29, 2011 Slideshow ★ to Karachi. Stunning free travel slideshows on TripAdvisor"

Tuesday, 31 May 2011

Mechanical Draft

New Punch

Objective:

- Circle

- Array

- Mirier

- Deimantion tools

| ||||||

| New Die |

Objective

- Circle

- Line Coordination

- Hatch

- Arc

- Champers

- Redus

- Mirror

Breaket

Objective- Line

- Cilcle

- Diemation

|

| Bend Bracket |

- Rectangle

- Arc

- Circle

- Redus

- Champers

| |

| New Spandel |

- Line

- Threading

- Arc

- Circle

- Diemantion

Drawing By Atif Raees

Monday, 30 May 2011

Sheet Metal Die Designer

|

| Sheet Bending |

|

| Sheet Metal Die |

| |

| Sheet Metal Die Bending |

It’s a good idea to start with the basic definition of sheet metal. Sheet metal can be classified or can be understood as a flat metal sheet. Depending on its thickness it is either called a leaf/foil or a plate. Very thin metal sheet is called a leaf foil and metal sheets thicker than 6mm are called as plates. Sheet metal is one of the basic forms of manufacturing where the metal sheets are cut and bent into various forms depending upon various needs and uses. Normally there are two processes involved in Sheetmetal fabrication they are Deep Drawing and Flat Rolling. Now let us look at these two processes with some detail.

Deep Drawing Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered “deep” drawing when the depth of the drawn part exceeds its’ diameter. This is achieved by redrawing the part trough a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Draft Designed By

Atif Raees Ahmad Noor

Auto Cad 2010 Commands:

- 3D Creates three-dimensional polygon mesh objects

- 3DARRAY Creates a three-dimensional array

- 3DCLIP Invokes the interactive 3D view and opens the Adjust Clipping Planes window

- 3DCORBIT Invokes the interactive 3D view and enables you to set the objects in the 3D view into continuous motion

- 3DDISTANCE Invokes the interactive 3D view and makes objects appear closer or farther away

3DFACE Creates a three-dimensional face - 3DMESH Creates a free-form polygon mesh

- 3DORBIT Controls the interactive viewing of objects in 3D

- 3DPAN Invokes the interactive 3D view and enables you to drag the view horizontally and vertically

- 3DPOLY Creates a polyline with straight line segments using the CONTINUOUS linetype in three-dimensional space

- 3DSIN Imports a 3D Studio (3DS) file

3DSOUT Exports to a 3D Studio (3DS) file - 3DSWIVEL Invokes the interactive 3D view and simulates the effect of turning the camera

- 3DZOOM Invokes the interactive 3D view so you can zoom in and out on the view

Labels:

Sheet Metal Die

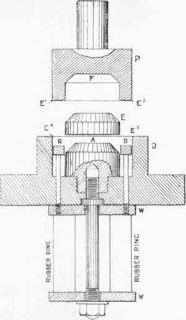

PILLOW BLOCK BEARING

OBJECTIVE:

Type SA-PB Pillow Blocks and Flange Blocks are a uniquely designed compact unit (Patented) requiring minimum support space. These units are self-aligning, ruggedly constructed and suitable for non- lubricated heavy duty applications. Fitted with a variety of Metcar Self-lubricating Bearing Grades which can be operated dry or submerged to temperatures of 1000º F.Special features of these heavy duty units are:

- Completely self-aligning (compensate for shaft deflection and misalignment)

- Can be used dry or submerged to temperatures of 1000º F.

- Replaceable Bearing Cartridge can be rotated 180º for double life (no need to remove from shaft)

- Interchangeable with most standard ball bearing pillow and flange blocks.

- Operate freely and quietly under heavy loads

- Can be modified for thrust loading

- 10 sizes available for shafts up to 3-3/8″

- 2 Standard Bearing Cartridge lengths available (A and A-Ext.) Bearing length (A) medium duty applications, bearing length (A-Ext.) heavy duty applications.

- Unlimited Bearing Cartridge length available for unusual load and speed conditions.

| PILLOW BLOCK BEARING |

Labels:

PILLOW BEARING

COPY LATHE MACHINE

OBJECTIVE

The lathe machine is the most common machine tool machinery. Which remove material by rotating the work piece against a single point cutter. Parts can be held between centers, attached to a face plate, supported in a jaw chuck. Although this machine is particularly adapted for cylindrical work, it may also be used for other operations.| COPY LATHE MACHINE |

NEW SHAPER MACHINE

OBJECTIVE:

A shaping machine is used to machine surfaces. It can cut curves, angles and many other shapes. It is a popular machine in a workshop because its movement is very simple although it can produce a variety of work. Shaping machines come in a range of sizes but the most common size is seen below.The main parts are indicated below:

The tool feed handle can be turned to slowly feed the cutting tool into the material as the ‘ram’ moves forwards and backwards. The strong machine vice holds the material securely. A small vice would not be suitable as the work could quite easily be pulled out of position and be damaged. The vice rests on a steel table which can be adjusted so that it ca be moved up and down and then locked in position. Pulling back on the clutch handle starts the ‘ram’ moving forwards and backwards.

| High-Speed-SHAPER MODEL NO-MX5068- |

PRODUCT DESCIRIPTION

High Speed Router MX5068 Since the establishment of our company, we have won the most business through our excellent products, honest operation and fist-rate service.Nowadays, we are developing the international market actively. Our products sales to Africa, Europe Latin America and weur have made great achievement.

| Specification and model | MX5068 | |

| Working table size | 805× 600mm | |

| Working table lift stroke | 180mm | |

| Max. workingpiece thickness | 150mm | |

| ax. spindle stroke | 65mm | |

| Distance between spindle | 730mm | |

| Cutter handle dia. | 12.7mm | |

| Spindle speed | 18000r/min | |

| Install power | 3kw |

Punching machine

|

| Punching machine |

Articles:

| we provide a wide range of Hydraulic Paper Cutting Machine to our customers. Hydraulic Paper Cutting Machine and other paper cutting machines offered by us are made of quality material and feature optimum functionality standards. These machines are very easy to operate as well as allow easy cutting of paper according to your requirements.Our range of binding machines include Hydraulic fully automatic paper cutting machines. This machine is designed by our experts for enhanced performance. It helps to enhance production and saves timeand labor needed for production. The Hydraulic Paper cutting Machines are all designed to deliver accurate results with easy operation facilities. All our Hydraulic Paper cutting Machines equipment is provided with safety devices. These machines can be easily installed with minimum space requirements. Hence our range of binding machines not only enhance the production capacity but also provide a safe and spacious work area. | |

| Specifications: | |

| Magnetic Clutch and brake for easy control | |

| Infra Red Safety device is also installed | |

| Cutting line indicator is also provided | |

| Two hand push button for safety while cutting | |

| Hydraulic self clamping provide | |

| Motorized back gauze. |

Labels:

Punching machine

Sunday, 29 May 2011

Shaper Machine

Shaper machine supplied by us is fabricated with utter technical perfection. Efficient in their performance, our array of shaper machine executes spontaneity in their functional ability. Manufactured in compliance with standard international norms, these shaping machines are helpful in perfect shaping of several industrial & uneven materials. Available in variable specifications, we also offer customization facilities to our entire range of Shaper Machines. The shaper machines that we supply are given below:

Specifications:

|

Shaper Machines

Extensively used in various sectors, gear type shaping machine is one of the massively demanded sheet metal machines. This machine is widely demanded because of their significant features such as high performance, condensed construction, sturdiness and long utility life. This Shaper Machines are fabricated in conformity with various international industrial standards and offered at maximum size between 18" to 42". Along with their standard set of production, we also provide customization facilities to our clients on the basis of their detailed descriptions. Specifications:

Surface Grinder

| Surface Grinder Machine |

Surface Grinder Machine

Surface grinder which includes the wash grinder. A surface grinder has a "head" which is lowered and forth past the grinding wheel on a table that has a permanent magnet for use with magnetic stock. Surface grinders can be manually operated or have CNC controls.

Grinding machines remove material from the workpiece by abrasion, which can generate substantial amounts of heat; they therefore incorporate a coolant to cool the workpiece so that it does not overheat and go outside its tolerance.

Casting Processes

Aluminum Casting

| Casting Aluminum |

Trident Components offers aluminum die or metal casting. Aluminum is a versatile metal alloy, suitable for all of your metal casting needs. Because of its advantageous properties, aluminum cast parts are highly valued in a variety of applications in many of today’s major industries. We also have advanced production facilities and cost-effective warehousing services to meet all your Aluminum die or metal casting needs.

Brass Casting

Trident Components offer brass metal casting, or die casting. Brass is an amazing alloy, and Trident Components can customize all your brass metal casting orders. Brass has the strength and corrosion resistance that make it ideal for a variety of applications. Our casting processes and warehousing facilities give us the ability to accommodate any size order and meet virtually any brass casting need, all at competitive prices.The properties of brass alloys are affected by their composition.

Chromium Steel

Trident Components offer chromium steel/stainless steel die casting. Chromium steel, also known as stainless steel, is an alloy of chromium and steel, and Trident Components offers it for all of your die casting needs. All of our materials, warehousing facilities, and production capabilities will give you an economical and accurately-cast part. Trident Components is highly experienced in working with all grades of stainless steel suitable for almost any application.Bending Sheet draft

| Bending Sheet |

Sheet Metal Stamping

Trident Components is a specialist in sheet metal stamping. Our processes and equipment produce top-quality components at a piece part price you can handle. And our sheet metal stamping services present you with a lean manufacturing solution unmatched in the industry.Sheet Metal Stamping

Trident Components has designed its sheet metal stamping processes to achieve top quality at a low price. Our tooling is extremely inexpensive – generally 50% of our competitors’ costs. And our piece part prices are 10-20% less expensive. All this translates to tremendous savings for our customers. Unlike many sheet metal stamping companies which offer only one form of stamping, Trident is proud to offer the following sheet metal stamping services:- Modular stamping

- Progressive die stamping

- High-speed stamping

- Deep draw stamping

- Bore slide stamping

- Transfer stamping

Our sheet metal stamping services:

- yield dimensionally precise parts

- are dependable and cost-effective

- ensure orders are accurate and on time

Labels:

Bending Sheet

Autocad Drafting

Articles :

Die clearance is the amount of clearance between a punch and a die. The optimal clearance can be determined by two factors: material thickness and material type. For thinner material, the clearance should be as tight as possible to prevent ragged edges. However, for thicker material the clearance should be larger to allow the perforating process to be successful without damaging the punch and the die and to give a good edge quality.

According to Machinery’s handbook 27th edition, page 1329, there are two definitions of clearance among top die makers. The first and the most commonly used one is that a clearance is the space between the punch and the die on one side. If we take a round punch tool as an illustration, according to this definition, the clearance will be the die radius minus the punch radius. On the other hand, the second definition says that the clearance is the total difference between the die and the punch. For example, if the die is 12.8mm round and the punch is 12.7mm round, the clearance according to the second definition will be 0.1mm. But, according to the first definition, the clearance will be 0.05mm.

According to Machinery’s handbook 27th edition, page 1329, there are two definitions of clearance among top die makers. The first and the most commonly used one is that a clearance is the space between the punch and the die on one side. If we take a round punch tool as an illustration, according to this definition, the clearance will be the die radius minus the punch radius. On the other hand, the second definition says that the clearance is the total difference between the die and the punch. For example, if the die is 12.8mm round and the punch is 12.7mm round, the clearance according to the second definition will be 0.1mm. But, according to the first definition, the clearance will be 0.05mm.

In order to avoid any misconception about the clearance, I recommend consulting the sales team where you have purchased your tool and die (e.g. Wilson tooling or Mate tooling).

On this page, I would like to share some useful articles and information regarding die clearance.

Mechanical Draft

Article:

A developer of new plastics technologies is applying low-temperature die drawing to take advantage of a new raw material: expanded, oriented, wood-filled polypropylene (EOW-PP). It looks and feels almost indistinguishable from natural wood but is 150% stronger. It’s also 300% stronger than ordinary PP and close enough to the strength of steel that the term “plastic steel” is no great exaggeration.“We haven’t been able to break it yet. It just bends,” says Frank Maine, president of SHW (Synthetic Hardwood) Technologies Inc. in Guelph, Ont., the developer of EOW-PP.

This unusual new material is made by a combination of two metalworking processes: solid-state extrusion and die drawing. Solid-state deformation processes like ram extrusion are typically used to shape high-value, non-melting plastics like UHMW polyethylene and PTFE into tubes and sheets, not to form inexpensive commodity resins. Orienting of PP film and fiber is commonplace, but orienting a solid PP profile has been limited to lab work in a few universities.

In the early 1990s, researchers at the Aluminum Company of Canada Ltd. (Alcan) in Kingston, Ont., spent six years ram extruding unmelted PP into highly oriented rods of enormous strength. The process requires two steps. First, PP is extruded conventionally into billets—solid, round, or rectangular profiles that are cut to 15-20 in. lengths. The billets are then heated to slightly below the melting point and are ram extruded with a very high draw ratio into thin profiles. Haul-off tension around 450 psi keeps the profiles from relaxing before they cool.

| Bending Machine |

Alcan patented the process and material but halted the project after the price of aluminum plunged. Symplastics Ltd. in Orangeville, Ont., a plastics processor already experienced in deformation processing of UHMW-PE sheet, bought Alcan’s patents and lab line and spent three more years of R&D on the process.

After three years, Symplastics’ only commercial success with the OPP profiles were small rods made for Frank Maine, who machined them into unbreakable drumsticks for musicians. “Drummers objected to the look of the plastic,” Maine recalls. “They liked the performance of the PP drumsticks, but wanted the sticks to look like wood.”

So Symplastics added 8% wood flour to the billets, which made the rods look and feel remarkably like wood. Wood-filled rods acquired less orientation but still had impressive strength. Eventually Symplastics found the R&D too costly and sold the patents and lab line to Maine, who set up SHW to try to commercialize more applications for the super-strong material.

One such application is unfilled OPP beams for automotive side-impact bars, which were tested recently side by side with steel beams. The load at failure for OPP was 30% below that of steel. But while the steel beam snapped when it failed, the OPP beam only delaminated. These preliminary test data were released earlier this month at the Society of Automotive Engineers show in Detroit by Dr. Phillip Bates, Assoc. Prof. at the Royal Military College in Kingston, Ont.

Die drawing also went much faster—up to 30 ft/min, vs. 4 ft/min for ram extrusion alone. At such a speed, it may be possible to run billet extrusion in line with die drawing, Maine speculates. And with die drawing, Maine doesn’t need to use the ram, thereby saving energy. Pushing the billets takes 3000 psi, but die drawing takes only 1800 lb of tension to do the same work. The ram now only pushes the first 5 in. of the billet through the die, enough for the puller to grab.

Die drawing may allow larger profiles to be oriented. Ram extrusion of unfilled PP is limited to small rods, probably not over 1 in. diam., because orientation takes place only in the resin close to the compression-chamber walls. The larger the profile, the greater the ratio of weaker, unoriented core to stronger, oriented skin. Maine speculates that die drawing of wood-filled PP may cause the orientation to be more evenly distributed across the profile.

Maine says die drawing can also speed the solid-state extrusion of unfilled PP. He has not yet tested the resulting product to ascertain the level of property improvement in unfilled material.

Labels:

Mechanical Draft

Subscribe to:

Comments (Atom)