Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum). The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies, it rapidly cools and solidifies into the final part, called the casting. The steps in this process are described in greater detail in the next section. The castings that are created in this process can vary greatly in size and weight, ranging from a couple ounces to 100 pounds. One common application of die cast parts are housings - thin-walled enclosures, often requiring many ribs and bosses on the interior. Metal housings for a variety of appliances and equipment are often die cast. Several automobile components are also manufactured using die casting, including pistons, cylinder heads, and engine blocks. Other common die cast parts include propellers, gears, bushings, pumps, and valves.

Mechanical Designer

Friday, 17 June 2011

NewDie Casting

Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum). The differences between these machines will be detailed in the sections on equipment and tooling. However, in both machines, after the molten metal is injected into the dies, it rapidly cools and solidifies into the final part, called the casting. The steps in this process are described in greater detail in the next section. The castings that are created in this process can vary greatly in size and weight, ranging from a couple ounces to 100 pounds. One common application of die cast parts are housings - thin-walled enclosures, often requiring many ribs and bosses on the interior. Metal housings for a variety of appliances and equipment are often die cast. Several automobile components are also manufactured using die casting, including pistons, cylinder heads, and engine blocks. Other common die cast parts include propellers, gears, bushings, pumps, and valves.

Tuesday, 14 June 2011

May 29, 2011 Slideshow

May 29, 2011 Slideshow: "TripAdvisor™ TripWow ★ May 29, 2011 Slideshow ★ to Karachi. Stunning free travel slideshows on TripAdvisor"

Tuesday, 31 May 2011

Mechanical Draft

New Punch

Objective:

- Circle

- Array

- Mirier

- Deimantion tools

| ||||||

| New Die |

Objective

- Circle

- Line Coordination

- Hatch

- Arc

- Champers

- Redus

- Mirror

Breaket

Objective- Line

- Cilcle

- Diemation

|

| Bend Bracket |

- Rectangle

- Arc

- Circle

- Redus

- Champers

| |

| New Spandel |

- Line

- Threading

- Arc

- Circle

- Diemantion

Drawing By Atif Raees

Monday, 30 May 2011

Sheet Metal Die Designer

|

| Sheet Bending |

|

| Sheet Metal Die |

| |

| Sheet Metal Die Bending |

It’s a good idea to start with the basic definition of sheet metal. Sheet metal can be classified or can be understood as a flat metal sheet. Depending on its thickness it is either called a leaf/foil or a plate. Very thin metal sheet is called a leaf foil and metal sheets thicker than 6mm are called as plates. Sheet metal is one of the basic forms of manufacturing where the metal sheets are cut and bent into various forms depending upon various needs and uses. Normally there are two processes involved in Sheetmetal fabrication they are Deep Drawing and Flat Rolling. Now let us look at these two processes with some detail.

Deep Drawing Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered “deep” drawing when the depth of the drawn part exceeds its’ diameter. This is achieved by redrawing the part trough a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Draft Designed By

Atif Raees Ahmad Noor

Auto Cad 2010 Commands:

- 3D Creates three-dimensional polygon mesh objects

- 3DARRAY Creates a three-dimensional array

- 3DCLIP Invokes the interactive 3D view and opens the Adjust Clipping Planes window

- 3DCORBIT Invokes the interactive 3D view and enables you to set the objects in the 3D view into continuous motion

- 3DDISTANCE Invokes the interactive 3D view and makes objects appear closer or farther away

3DFACE Creates a three-dimensional face - 3DMESH Creates a free-form polygon mesh

- 3DORBIT Controls the interactive viewing of objects in 3D

- 3DPAN Invokes the interactive 3D view and enables you to drag the view horizontally and vertically

- 3DPOLY Creates a polyline with straight line segments using the CONTINUOUS linetype in three-dimensional space

- 3DSIN Imports a 3D Studio (3DS) file

3DSOUT Exports to a 3D Studio (3DS) file - 3DSWIVEL Invokes the interactive 3D view and simulates the effect of turning the camera

- 3DZOOM Invokes the interactive 3D view so you can zoom in and out on the view

Labels:

Sheet Metal Die

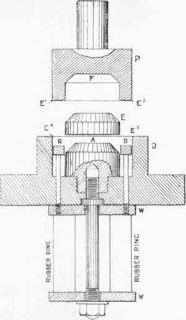

PILLOW BLOCK BEARING

OBJECTIVE:

Type SA-PB Pillow Blocks and Flange Blocks are a uniquely designed compact unit (Patented) requiring minimum support space. These units are self-aligning, ruggedly constructed and suitable for non- lubricated heavy duty applications. Fitted with a variety of Metcar Self-lubricating Bearing Grades which can be operated dry or submerged to temperatures of 1000º F.Special features of these heavy duty units are:

- Completely self-aligning (compensate for shaft deflection and misalignment)

- Can be used dry or submerged to temperatures of 1000º F.

- Replaceable Bearing Cartridge can be rotated 180º for double life (no need to remove from shaft)

- Interchangeable with most standard ball bearing pillow and flange blocks.

- Operate freely and quietly under heavy loads

- Can be modified for thrust loading

- 10 sizes available for shafts up to 3-3/8″

- 2 Standard Bearing Cartridge lengths available (A and A-Ext.) Bearing length (A) medium duty applications, bearing length (A-Ext.) heavy duty applications.

- Unlimited Bearing Cartridge length available for unusual load and speed conditions.

|

| PILLOW BLOCK BEARING |

Labels:

PILLOW BEARING

COPY LATHE MACHINE

OBJECTIVE

The lathe machine is the most common machine tool machinery. Which remove material by rotating the work piece against a single point cutter. Parts can be held between centers, attached to a face plate, supported in a jaw chuck. Although this machine is particularly adapted for cylindrical work, it may also be used for other operations. |

| COPY LATHE MACHINE |

NEW SHAPER MACHINE

OBJECTIVE:

A shaping machine is used to machine surfaces. It can cut curves, angles and many other shapes. It is a popular machine in a workshop because its movement is very simple although it can produce a variety of work. Shaping machines come in a range of sizes but the most common size is seen below.The main parts are indicated below:

The tool feed handle can be turned to slowly feed the cutting tool into the material as the ‘ram’ moves forwards and backwards. The strong machine vice holds the material securely. A small vice would not be suitable as the work could quite easily be pulled out of position and be damaged. The vice rests on a steel table which can be adjusted so that it ca be moved up and down and then locked in position. Pulling back on the clutch handle starts the ‘ram’ moving forwards and backwards.

|

| High-Speed-SHAPER MODEL NO-MX5068- |

PRODUCT DESCIRIPTION

High Speed Router MX5068 Since the establishment of our company, we have won the most business through our excellent products, honest operation and fist-rate service.Nowadays, we are developing the international market actively. Our products sales to Africa, Europe Latin America and weur have made great achievement.

| Specification and model | MX5068 | |

| Working table size | 805× 600mm | |

| Working table lift stroke | 180mm | |

| Max. workingpiece thickness | 150mm | |

| ax. spindle stroke | 65mm | |

| Distance between spindle | 730mm | |

| Cutter handle dia. | 12.7mm | |

| Spindle speed | 18000r/min | |

| Install power | 3kw |

Subscribe to:

Posts (Atom)